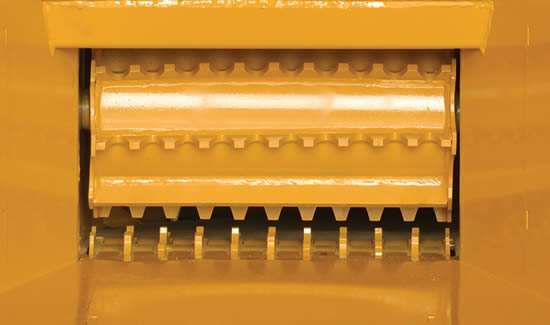

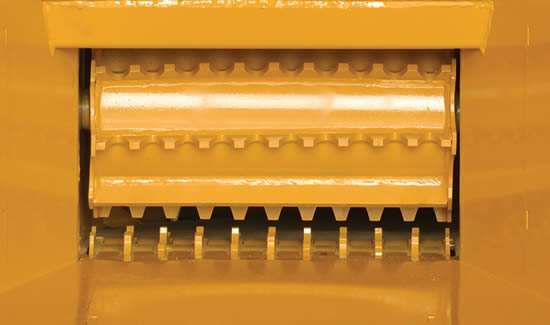

Rotor(Flywheel)

At the heart of the FRED BX Chipper is an oversize heavy duty rotor and reversible chipping blades. The large diameter rotor has a faster tip speed for improved chipping action and the heavy gauge steel keeps your momentum to power through 7'' diameter tree trunks.

Blades

The double sides cutting blades are precision cut tool steel and hardened, keeping a sharp cutting edge and maximizing the

performance of the chipper.

Air Vents

Blowing force is maximized with air intake vents on the side of the chipper. Air enters through the vents and powers the chips out the chute up to 20 feet.

Twig Breaker Blower Paddles

Behind the blades are blower paddles with integrated twig breakers designed for greater output force and smaller chips exiting the machine. This provides more consistent chip size and allows you to propel the chips further. Besides, solid cutting disc with holes so that it can be locked for maximum safety during maintenance.

Adjustable Chute

Easily control where you want the chips with the double adjustable Exit Chute. The chute swivels 360 degrees and the top deflector adjusts the distance.

Hydraulic Feed Hopper

Maximize your chipping with the aggressive hydraulic feed hopper. Chipping becomes effortless when you let the rotating teeth do all the work. As the brush is fed into the hopper, you can be ready with the next piece.

PTO Drivetrain, Shear bolt protected

Pick Your Own Color

Slab Style Opening

Adjustable Top Infeed Roller Height

Easy Start Tension Relief

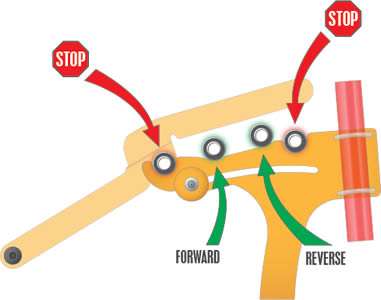

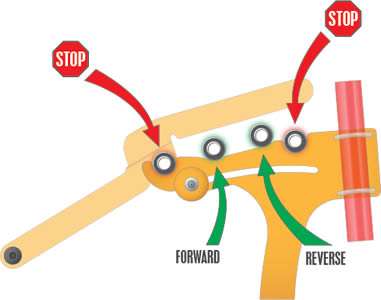

Safety Control Handle

4-position infeed function: Stop, Forwards, Backwards and Stop. For maximum control, function and safety.

Safe transportation when the feed hopperis closed in transport mode

Adjustable discharge hood height-This is for Option

Hydraulic Control Valve Hydraulic Compensation valve Cutting Knife

Hydraulic Control Valve Hydraulic Compensation valve Cutting Knife

Hydraulic Pipeline Oil Tank Cap Oil Tank Filter

Hydraulic Pipeline Oil Tank Cap Oil Tank Filter